Excel Data Import | Printer Module | CAE Modeler Component for Rate Dependency | CAE Material File Information

Matereality Version 10.2 release introduces new features for importing data from Excel; producing reports directly from Matereality libraries; enhancing LS-DYNA and RADIOSS CAE Modelers to better handle rate dependent models; including additional traceability information in CAE Material files; and exporting material library files to CAE software.

Many companies store their material data in Excel worksheets. A newly released, free-form data, Excel-based importer allows users to capture data in these legacy Excel worksheets directly into Matereality. For example, a spreadsheet may contain tensile properties including stress-strain data, modulus, yield and Poisson’s ratio, in addition to test parameters such as crosshead speed, specimen dimensions and temperature. Users create a one-time data map to identify the locations of the data to be read. A conversion macro then creates a file that can be imported into Matereality. This new feature greatly speeds up the process of capturing the material data of the enterprise into the Matereality libraries, allowing for large amounts of simple and complex data to be imported in quickly and easily.

Figure 1. Workflow for importing Excel data

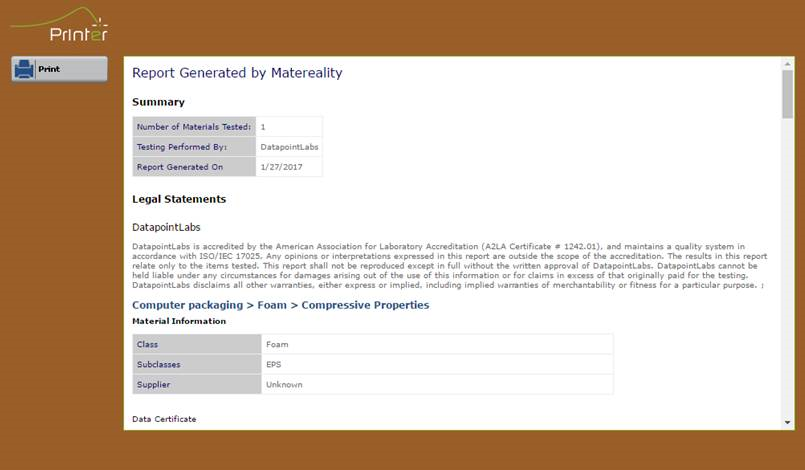

Matereality’s new Printer module lets users print material data test reports directly from Matereality. Features including automated cross-plotting of data and unit conversion, which saves time and effort in the interpretation of complex multi-variate data. Users can also zoom and do variability bands around the data. Printed PDF reports can be stored in the Reports library, attached to the digital data from which they were generated.

Figure 2. New Printer module

A new CAE Modeler software component has been released that takes into consideration the unique multi-variate nature of LS-DYNA and RADIOSS material models. Rate-dependent models require adjustment and tuning of many material parameters to fit the rate-dependent tensile properties. The new CAE Modeler interface provides drag-and-drop capabilities to allow users to perform tasks such as model extrapolation beyond tested data, modulus change, rate dependency tuning and failure criteria adjustment, while assuring self-consistency of the underlying material model. Unit system conversions are also facilitated, eliminating error and ensuring that material inputs to simulation correctly reflect the intent of the CAE analyst. The new generation CAE Modelers are available for LS-DYNA material models MAT_019, MAT_024 LCSS and LCSR, and MAT_089 LCSR; and for Altair RADIOSS.

Figure 3. Modeler module for RADIOSS Law36

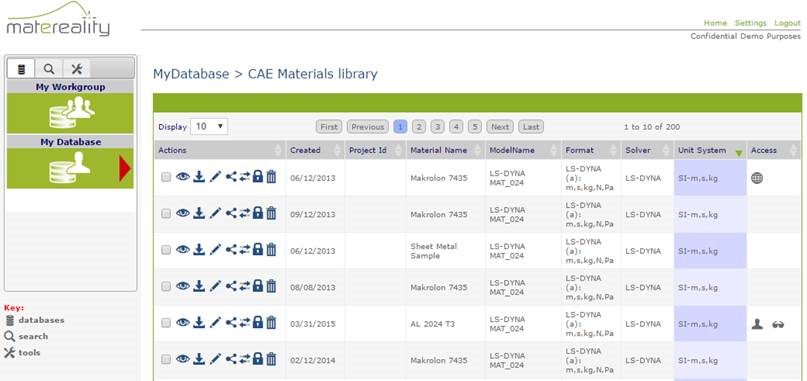

We have augmented the CAE Material file documentation to include solver names and unit system as additional attributes to the CAE Materials library. These attributes can help select and deploy material files to the right solvers and in consistent units, particularly when deploying material file libraries for Altair Hyperworks and ANSA software.

Figure 4. New attributes available for CAE Material file traceability

We have also released material library export formats for NX, CATIA and CREO which contain master materials identification that can be used in their BOMs. The same materials identification is used to tag the material files we send to CAE pre-processors like ANSA and Hyperworks. This process is intended to ensure consistent material names are used for all simulations. A material specification-based output is also available for Enterprise customers.

Figure 5. Export linear CAE data with master materials indentification

Please send any questions or comments to support@matereality.com